Green Steel Market

Green steel is environmentally friendly steel produced by reducing its carbon footprint as compared to the conventional steel-making process. The reduction in this footprint is obtained through the implementation of non-coal-based alternative technologies. Green steel production utilizes green hydrogen instead of coal and electricity generated from fossil-free sources

For customized market research, insightful consulting, or expert advisory services, drop a query at reports@analyticscompass.com

Green steel is environmentally friendly steel produced by reducing its carbon footprint as compared to the conventional steel-making process. The reduction in this footprint is obtained through the implementation of non-coal-based alternative technologies. Green steel production utilizes green hydrogen instead of coal and electricity generated from fossil-free sources

Current steel production generate around 8% of global CO2 emissions. To bring the sector in line with a 2050 net-zero target, process emissions must fall by at least 30% by 2030

The transition is under way to move steel production away from coal-fired furnaces to ones powered by electricity or hydrogen. Producing green steel is an expensive process. The industry needs to scale up to hit net-zero targets. To reduce the environmental impact of greenhouse gas emissions, industry experts are now turning towards a sustainable steel-making process that has the potential to bring the global CO₂ emissions close to zero

Green steel is one such endeavor to produce steel to have the lowest possible carbon footprint during production. It is believed the green steel production process reduces the CO₂ emissions by 95% as compared to the traditional steel-making process

The construction and automotive sectors account for more than 60% of steel demand globally (52% and 12% respectively), followed by the machinery, metalware and energy sectors

— According to World Steel Association, in 2020, 1,860 MT (Million tons) of steel was produced globally, which contributed to an average of 1.851 tons of CO2 into the atmosphere . 1 ton of steel production using the traditional methods roughly releases 2 tons of CO2 into the atmosphere and the world uses more than 2 billion tons of steel each year

Growth Driver for Green Steel

- Rising shift towards Green steel production by steel manufacturers to achieve net-zero emissions leading to decarbonising of the steel industry

- The surging demand for low-carbon steel from various end-user industries, such as automotive, building & construction is also expected to rise with their targets to use sustainable products

- The global market is likely to be driven primarily by the inclination of governments in the US, Canada, Germany, France, the UK, etc., toward lowering carbon emissions & adopting sustainable products & manufacturing practices in verticals, such as construction, electronics, industrial equipment

- Green steel has the lowest possible carbon footprint during production. It is believed the green steel production process reduces the CO₂ emissions by 95% as compared to the traditional steel-making process

- To meet climate goals, the steelmaker have a target to decarbonise the process. “Green” hydrogen, renewable electricity and electric arc furnaces will be critical to the transition

- Introduction to Green Steel

- Global Green Steel Market

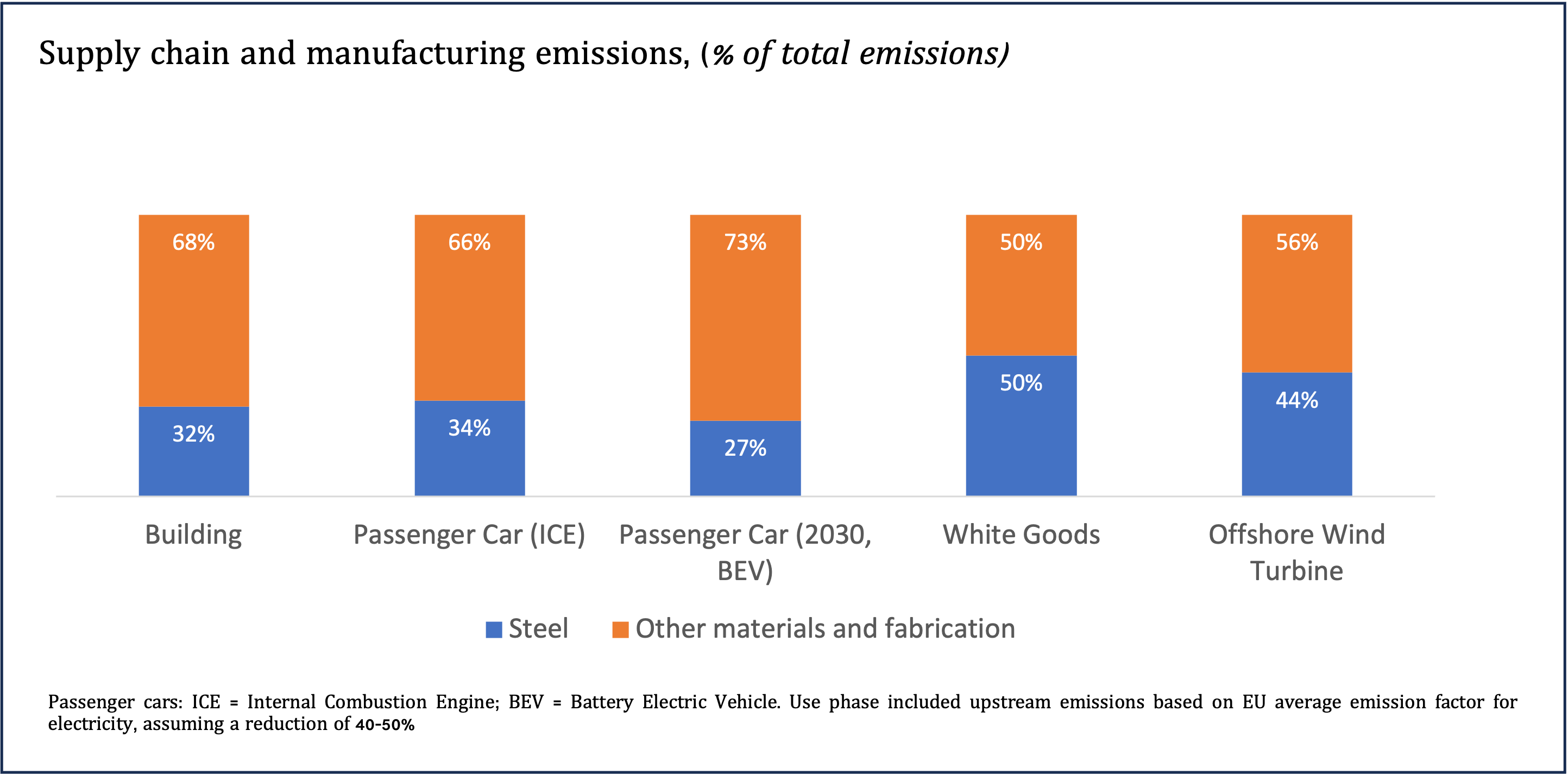

- Steel share of materials and manufacturing emissions in several key products

- Steel Production Process and CO2 emission in steel making

- Role of Hydrogen in Steel making

- Cost of making Steel

- Investment in Green Steel

- Iron & Steel Production Process

- Trends in Green Steel Making

- Iron & Steel Market

- 5 Company Profiles

- Arcelor Mittal

- Nippon Steel

- Tata Steel

- HBIS Limited

- United States Steel